Background: The traditional screw locking operation mainly uses manual locking screws, which not only has low production capacity, product appearance is easily scratched, quality is unstable, and the defect rate is high, but also the labor demand and labor intensity are high, which greatly increases the production cost.

Industry Status: With the development of automation technology, the automatic locking screw machine has solved this problem very well. The automatic screw locking machine establishes the automatic conveyor, tightening, inspection and other technological processes of screws according to various electric and pneumatic electronic devices, and simplifies the screw tightening process according to the machinery and equipment.

With high efficiency, high stability, high High quality, realizing the advantages of high intelligence and unmanned operation of lock and payment operations. It plays a key role in improving the production efficiency and product qualification rate of the enterprise, reducing the labor intensity of employees and production costs.

Applications:The automatic locking screw machine mainly collects the workpiece locking point information through the vision system, and the industrial computer processes the image information to form coordinate points then sends it to the PLC or robot controller. The industrial computer is equivalent to the human brain for the automatic locking screw machine equipment.

Therefore, reliability, high efficiency and safety are the hard indicators for choosing an industrial computer, which needs to meet the following characteristics:

Therefore, reliability, high efficiency and safety are the hard indicators for choosing an industrial computer, which needs to meet the following characteristics:

➤Industrial ultra-thin and compact design

➤ Support HDMI, VGA display output

➤ Support WiFi/4G wireless extension

➤ Anti-vibration design, good stability and durability, can ensure long-term all-weather non-stop work

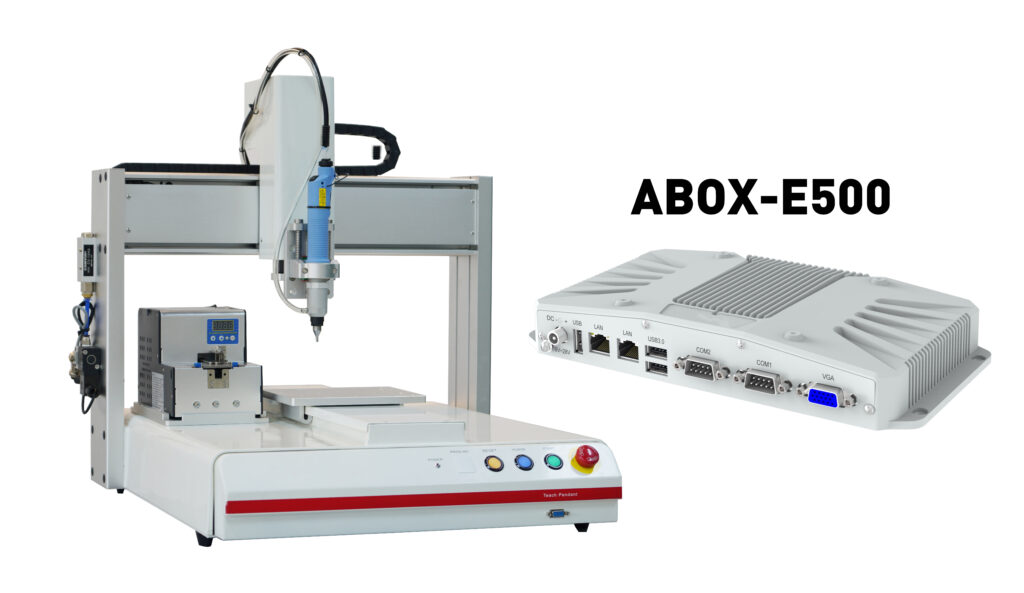

How ABOX-E500 help in this case?

The new ultra-thin and compact ABOX-E500 product adopts diamond cutting process design, and cooperates with die-casting molding and cable-free process to show quality and stability. The whole machine is developed based on the Intel Bay Trail platform, directly onboard high-speed memory, effectively resisting vibration and shock. The reverse-mounted zero-distance fanless cooling solution, coupled with wide-voltage power input performance, can meet various harsh industrial application scenarios, and the integrated Intel dual network ensures efficient and accurate terminal data collection, monitoring, and control.

Suitable for a variety of embedded and terminal applications.

Mainly have the following advantages:

➤Using Atom’s 4th generation Bay Trail ultra-low power single-chip processor

➤Integrated dual Intel Gigabit network with jumbo frame support

➤No fan cooling, 9~28V DC wide voltage power supply support, more stable operation

➤Support desktop, wall-mounted, and VESA installation methods, and the ultra-compact body is suitable for more embedded environments.

In conclusion: The automatic locking screw machine control system based on ABOX-E500 control has excellent performance and high reliability, and realizes the advantages of high production capacity, low cost, accurate torque control, and reduced labor intensity of the automatic screw locking machine.