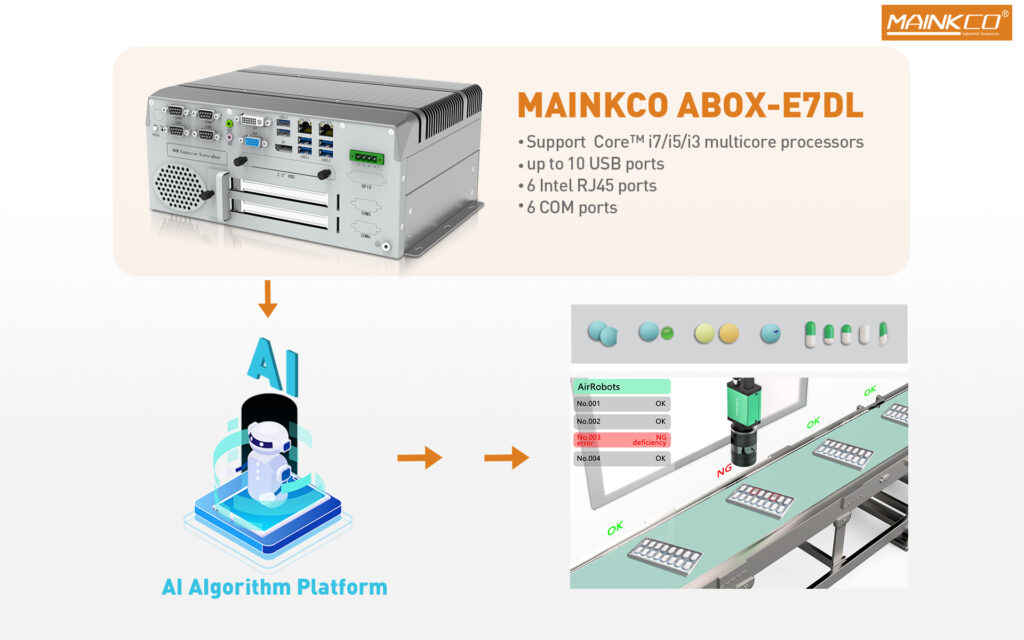

AI technology to solve the problem of high accuracy to detect a large number of pills, it uses from all angles qualified pill images for training, then defect detection tool can detect abnormal tablets, even the original training set, and let all qualified tablets into the main packaging steps, the final pill intact to the final consumer hand, improve brand reputation and minimize the risk of recall.

Tablet defect detection is a key link in the process of pill production, and the test results directly affect the quality of drugs. Common manual detection methods have high cost and low efficiency, and are easy to produce false detection and missing detection, which cannot meet the requirements of modern enterprises for product quality. Machine vision detection is widely used in the pharmaceutical industry with its high degree of automation, low cost and high efficiency.

MAINKCO Solution:

Through Ethernet / IP protocol data interaction, image acquisition, AI Edge computing Box PC ABOX-E7DL using Ether CAT motion control, check the image and automatic judgment, record data notify the host computer and show the test results, combined with the AI inference system directly inference, flexible third party algorithm platform (support secondary development) management, improve the detection rate, reduce the phenomenon such as error and omission.

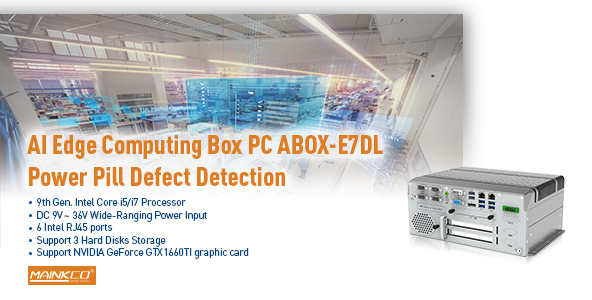

The ABOX-E7DL is designed for machine vision, Edge computing, machine learning/reasoning, robot control, factory automation, and more.

Support Intel 6th/7th/8th/9th Core i7/i5/i3 desktop multicore processors

Q170 (Alternative C236) industrial chipset

2 DDR4 SO-DIMM, Dual channels, MAX. up to 32GB

3 Display ports, support 3 hard disks storage

expansion up to 10 USB ports, 6 Intel RJ45 ports, 6 COM ports

Max. up to support Cambricon MLU270-S4 AI card (128TOPS)

Max. up to support NVIDIA GeForce GTX1660TI graphic card

2 standard PCIe expansion slots

Support wide voltage DC 9V ~ 36V power input

The end:

AI Edge computing Box PC ABOX-E7DL solve the problem of high accuracy to detect a large number of pills, it uses from all angles qualified pill images for training, then defect detection tool can detect abnormal tablets, even the original training set, and let all qualified tablets into the main packaging steps, the final pill intact to the final consumer hand, improve brand reputation and minimize the risk of recall.