Industrial control machine is more and more widely used in food testing, its main function is to improve the degree of automation and intelligence in the process of food production, processing and quality testing, reduce the intervention of manual operation, so as to improve the quality and safety of food production. The following will introduce the application and advantages of industrial control machine in food detection in detail.

一.Application in food production

-

Temperature and humidity control:

In the process of food production, temperature and humidity control is very important for food quality and preservation. The industrial control machine can realize the automatic temperature and humidity control of the food production environment by connecting multiple sensors and actuators, so as to ensure that the food is always in the appropriate temperature and humidity environment during the production process.

-

Process control:

The industrial control machine can connect multiple sensors and actuators to realize the automatic control of each link in the food production process, including the mixing, mixing, baking and other links of raw materials, so as to ensure that the control and monitoring of each link in the food production process can reach the best state.

-

Data management:

The amount of data generated in the food production process is very large, and it is very inefficient by only manual recording and management. The industrial control machine can realize the real-time recording and management of the food production data by connecting the database, so as to ensure the accuracy and real-time performance of the production data, and make it convenient for the enterprise managers to conduct data analysis and decision-making.

二.Application in food testing

-

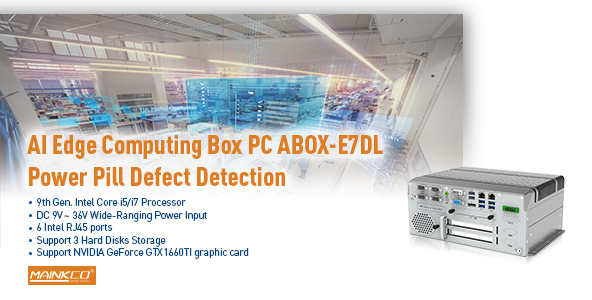

Test equipment control:

Food detection requires the use of a variety of testing equipment, such as spectrometers, electrochemical sensors, etc. The industrial control machine can be connected to realize the control and monitoring of the detection equipment, to ensure the accuracy and reliability of the detection data.

-

Test data processing:

The data generated in the process of food testing needs to be processed and analyzed to obtain the test results. The industrial control machine can realize the processing and analysis of the test data by connecting the database and the algorithm model, so as to obtain the test results, and evaluate and predict the test results.

-

Data visualization:

The detection results need to be presented in a visual way to facilitate enterprise managers to conduct data analysis and decision-making. The industrial control machine can connect the display devices to realize the visual presentation of the testing results, including data charts, videos and reports, so as to help the enterprise managers to better understand and master the food testing data, and then make more accurate and scientific decisions.

三.Advantages of industrial control machine in food detection

-

High degree of automation:

By connecting multiple sensors and actuators, the industrial control machine can realize the automatic control of food production and detection process, reduce the intervention of manual operation, thus improve the efficiency of production and detection, and reduce labor costs.

-

Fast data processing speed:

The industrial control machine can realize the real-time processing and analysis of food production and detection data by connecting the algorithm model and database, so as to obtain accurate detection results. At the same time, it can also visualize the data, which is convenient for managers to conduct data analysis and decision-making

-

High detection accuracy:

The industrial control machine can realize the control and monitoring of the food detection data by connecting multiple testing equipment, so as to ensure the accuracy and reliability of the detection data. At the same time, it also can process and analyze the data to further improve the detection accuracy.

-

Convenient data sharing:

The industrial control machine can realize the sharing and transmission of production and detection data by connecting the internal network of the enterprise, facilitate the cooperation and communication between different departments, and improve the work efficiency and collaboration ability within the enterprise.

To sum up, the application range of industrial control machine in food detection is very wide, including food production and testing and other links. Its advantages are mainly reflected in the high degree of automation, fast data processing speed, high detection accuracy and convenient data sharing. Through the application of the industrial control machine, it can effectively improve the quality and safety of food production and testing, and make a positive contribution to the development of the food industry.