Background:

Electric power inspection is a very important but dangerous industry, which is related to people’s production and life. At present, the length of smart grid lines in china has covered wide range distance and exceeded 1 million kilometers. So, traditional manual inspection is low-automated, high cost, and low coverage. Now, the data accumulation process is arduous, but cannot match the full coverage of line inspections, Intelligent automatic identification of faults. So manual inspection now cannot adapt to the development needs of the electric power inspection industry.

Industry status:

Intelligent robot inspection is an efficient, stable, and important method for electric power systems. Compared with the traditional manual inspection method, the advantages are more obvious and comprehensive. It has received more and more attention from various industries in the power industry and related industrial inspection industries.

Industrial Requirement:

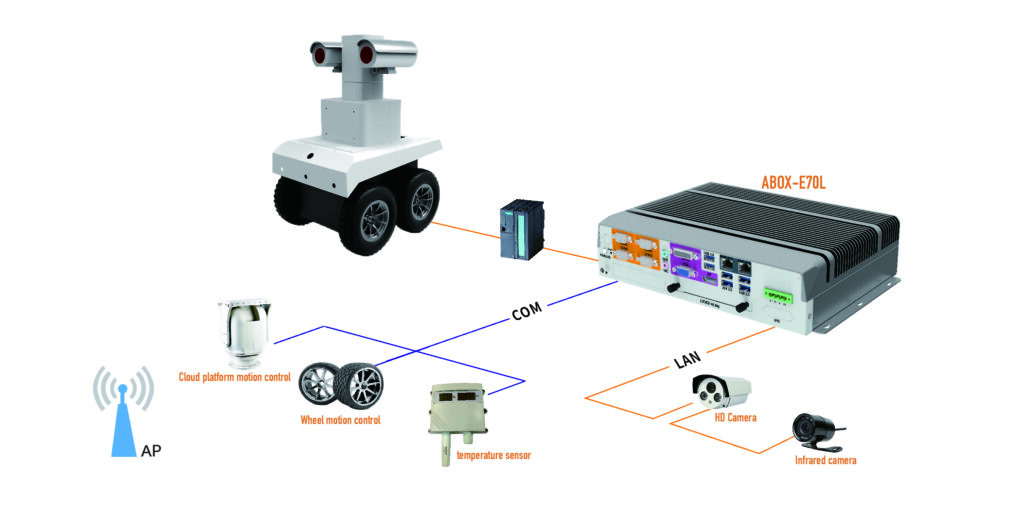

The electric power inspection robot is an intelligent inspection platform that integrates multi-sensors technology, robot motion control technology, embedded processing technology, navigation and behavior planning technology, robot vision, multiple information storage and wireless transmission.

Generally speaking, the power inspection robot receives inspection instructions from the monitoring center through the wireless network, follows the path specified by the system, uses the infrared system to measure the entire station equipment from different angles, and collects the temperature of the entire station equipment, so as to make intelligent analysis and diagnosis of equipment temperature data, realize the identification of equipment thermal defects and automatic alarm. Therefore, according to the application requirements of different areas in the substation, the industrial computing hardware required to meet the following conditions:

➤ The industrial computing device should be compact and small, and can be embedded into the robot under limited space;

➤ High-performance CPU processor, high computing capability of high-speed and large-scale calculations;

➤ Multiple I/O interfaces, convenient to connect various hardware devices;

➤ Rugged and robust design, anti-vibration design;

➤ Flexibly expandable solutions to add new functions to the system

Industrial Computing solution:

In order to meet the inspection requirements of inspection robots, Mainkco IPC provides a fanless AI vision computing hardware ABOX-E70L as the computing control core.

ABOX-E70L is an AI vision computing Box PC product developed based on the Intel LGA1151 6th/7th/8th/9th Desktop 35W CPU processors platform. It directly uses a full-performance desktop platform processor, combined with Intel Media SDK to achieve multi-channel graphics processing. In addition to the modular concept design, it also has multiple modules (aDoor and MXM modules) for the machine vision industry, and multiple high-speed I/O module interfaces. ABOX-E70L Box PC is designed with rich IO interfaces for industrial applications. In addition to high-performance computing and high-speed communication, it also supports 3 drives and support RAID 0/1 feature, providing a secure data warehouse, and through the combination of modules. The newly designed dynamic heat dissipation scheme and the molded aluminum alloy high-profile housing providing an ideal embedded design for vision computing applications.

Key feautres:

– Support Intel® 6th/7th/8th/9th Core™ i7/i5/i3 desktop multicore processors;

– Q170 (Alternative C236) industrial chipset;

– 2 DDR4 SO-DIMM, Dual channels, MAX. UP TO 32GB;

– 3 Display ports, support 3 hard disks storage;

– expansion up to 10 USB ports;

– expansion up to 6 Intel RJ45 ports;

– expansion up to 6 COM ports;

– Support wide voltage DC 9V ~ 36V power input.

Conclusion:

Whether the power inspection robot can be used flexibly and finish tasks effectively, its industrial computing hardware is the key. Mainkco IPC AI vision computing ABOX-E70L can meet the relatively high requirements of electric power inspection robots in terms of dimension, computing performance, safety, stability, expansion, etc., ABOX-E70L can be integrated into various types industrial inspection application system, to assist the inspection robot to effectively realize all-weather, all-round, and fully autonomous intelligent inspection of substations.