The core role of the support system is to ensure the efficience and stable operation of the manufacturing system. The main support system of intelligent manufacturing includes network communication, data management, information security, etc.

01

Industrial Internet

Industrial Internet is a link industry system, the whole industry chain and the whole value chain. It supports the development of industrial intelligent key information infrastructure, representing new generation of information technology and manufacturing depth fusion of emerging forms and application mode. Industrial internet means the Internet from consumption to production, from the virtual economy to the real economy of the core carrier, which finally means an important support of intelligent manufacturing technology and system.

The “Industrial Internet” concept was firstly released by General Electric in 2012. Then five leading US industry companies (AT & T, Cisco, GE, IBM and Intel) jointly formed the Industrial Internet Alliance (Industrial Internet Alliance, IIC) to promote and apply it. The core of the industrial Internet is to closely connect and integrate raw materials, equipment, production lines, factories, engineers, suppliers, products and customers through the industrial Internet platform, forming cross-equipment, cross-system, cross-enterprise, cross-regional, cross-industry interconnection, so as to improve the overall efficiency. It can help the manufacturing industry to lengthen the industrial chain and promote the intelligence of the entire manufacturing process and service system. It is also conducive to promoting the integrated development of the manufacturing industry, realizing the close interaction and leapfrog development between the manufacturing industry and the service industry, and realizing the efficient sharing of various elements and resources of the industrial economy.

As an important infrastructure for the development of industrial intelligence, the essence of industrial Internet is to make industrial can form data-driven intelligence based on comprehensive interconnection. In this process, industrial Internet can build three optimization closed-loops for the development of industrial intelligence:

(1) Closed-loop for operation optimization of machine equipment / production line. The core is to realize dynamic optimization and adjustment of machine equipment / production line through real-time perception and edge calculation of equipment / production line operation data and production link data, and build intelligent machine and flexible production line;

(2) The closed-loop for production and operation optimization. The core is to realize the dynamic optimization and adjustment of production and operation through the integration and fusion processing of information system data, manufacturing execution system data, control system data, and big data modeling and analysis, and to form the intelligent production mode in various scenarios;

(3) The closed-loop for enterprise collaboration, user interaction and product and service optimization. The core is to realize the innovation of enterprise resource organization and business activities through the comprehensive integration and analysis of supply chain data, user demand data and product and service data, and to form new modes such as network collaboration, personalized customization and service extension.

The Industrial Internet has delivered a major transformative impact on both the modern industrial production system and the commercial system. Based on the industrial perspective: the mode reform of industrial system and operation optimization at all levels, truthful monitoring, accurate control, data integration, operation optimization, supply chain coordination, personalized customization, demand matching, service value-added, etc.; the industrial Internet realizes the intelligent transformation of production organization and manufacturing mode from marketing, service and design, such as precision marketing, personalized customization, intelligent service, crowdsourcing, collaborative design, collaborative manufacturing, flexible manufacturing, etc.

02

5G technology

Intelligent manufacturing owns the functions of self-perception, self-prediction, intelligent matching and independent decision-making. In order to realize these functions, the data communication in the manufacturing process faces severe challenges, including high connection density, low power consumption, high reliability of communication quality, ultra-low latency, high transmission rate and so on. As an advanced communication technology, 5G can effectively address these challenges with lower latency, higher transmission rate, and ubiquitous connectivity. 5G technology makes it possible to apply wireless technology in new industrial application fields such as real-time control of field equipment, remote maintenance and control, and industrial high-definition image processing, and also lays a foundation for flexible production lines and flexible workshops in the future. With a transmission rate comparable to optical fiber, ubiquitous connectivity, and real-time capability close to industrial buses, 5G technology is gradually penetrating into intelligent manufacturing, opening up the future of wireless development in the industrial sector. With the development of intelligent manufacturing, 5G technology will be widely and deeply applied in various fields of intelligent manufacturing. The overall architecture of 5G + intelligent manufacturing mainly includes four levels: data layer, network layer, platform layer and application layer.

1)Data layer

Data layer based on sensors, video system, embedded system of data acquisition network, the product manufacturing process of various data information for real-time acquisition, including production equipment status, personnel information, workshop conditions, process information, quality information, etc., and using 5G communication technology data uploaded to the cloud platform, to form a set of efficient real-time data acquisition system. Through cloud computing, edge computing and other technologies, the data is processed efficiently in real time, so as to obtain the data analysis results, and provide real-time feedback through the data layer. On the one hand, it guides the whole production process, and on the other hand, it also provides a basis for the production optimization decision-making and closed-loop regulation of intelligent manufacturing.

The data layer realizes the complete collection of the data of the whole manufacturing process, providing massive multi-source and heterogeneous data for the optimization of manufacturing resources. It is the starting point of real-time analysis and scientific decision-making, and also the foundation of building an intelligent manufacturing industrial Internet platform.

2)Network layer

The network layer serves to provide better communication services to the platform layer and the application layer. As the network resource of enterprises, the 5G network with large-scale connection and low-delay communication can connect the massive production information in the factory, improve the timeliness of production data collection, and provide network support for production optimization, energy consumption management and order tracking.

The 5G technology adopted by the network layer can complete information reporting in a very short time to ensure the timelines of information, so as to ensure that production managers can form information feedback, accurately regulate the production environment, and effectively improve production efficiency. The network layer can also realize the real-time monitoring of the whole life cycle of remote production equipment, make the maintenance of production equipment break through the factory boundary, and realize the remote fault diagnosis and maintenance across factories and regions.

03

Database

A Database is “a warehouse that organizes, stores, and manages data according to the data structure.” It is a collection of large amounts of data stored, organized, shared, and uniformly managed for a long time. The database stores the data together in a certain way, and users can add, query, update, delete, share and other the data in the database through the interface. In intelligent manufacturing, database technology is an important guarantee for data analysis and processing, and also one of the important support systems for intelligent manufacturing.

In the history of database development, the database has experienced the development of hierarchical database, network database and relational database successively. The rapid development of database technology in various aspects, especially the relational database has become the most important member of the current database products. Since the 1980s, almost all the new database products of database manufacturers support relational databases, and even some non-relational database products almost all have interfaces to support relational databases. This is mainly because relational databases can better solve the problem of managing and storing relational data. With the development of cloud computing and the advent of the era of big data, relational database more and more cannot meet the needs of manufacturing, this is mainly due to more and more semi-related and nonrelational data need to use database storage management, at the same time, the emergence of new technologies such as distributed technology also put forward new requirements for database technology, so more and more nonrelational database by the attention of the manufacturing industry. This kind of database is very different from the traditional relational database in its design and data structure, which puts more emphasis on the high concurrent read and write and storage of database data. This kind of database is generally known as NoSQL (Not only SQL) database.

-1024x396.jpg)

Relational database refers to a database that adopts a relational model to organize data and stores data in the form of rows and columns for users to understand. Relational database This series of rows and columns are called tables, and a set of tables constitute the database. Relational models can be simply understood as a two-dimensional table model, and a relational database is a data organization composed of two-dimensional tables and the relationships between them. The relational database is easy to understand, operate and maintain. In the manufacturing industry, it is an indispensable core technology for building management information system, storage and processing of related data, such as ERP (enterprise resource planning, enterprise resource plan), MIS (management information system, management information system), EAM (enterprise asset management, enterprise asset management system) and other systems all use relational database for data processing.

The NoSQL database generally refers to non-relational databases. With the advent of the era of big data, data forms are diversified, and the traditional relational databases have appeared many problems that are difficult to overcome. NoSQL database is generated to solve the challenges brought by multiple data types of large-scale data sets, especially the problems of big data application. Compared with the traditional relational database, NoSQL database has the characteristics of easy scalability, high performance, high availability and high flexibility, which is easier to meet the application scenarios of pursuing speed, scalability and changeable business. More suitable for processing the unstructured data generated during the production process, such as pictures, text, etc.

3)Platform layer

The platform layer based on 5G technology provides intelligent support for the analysis and decision-making in the production process, which is one of the important cores of realizing intelligent manufacturing.

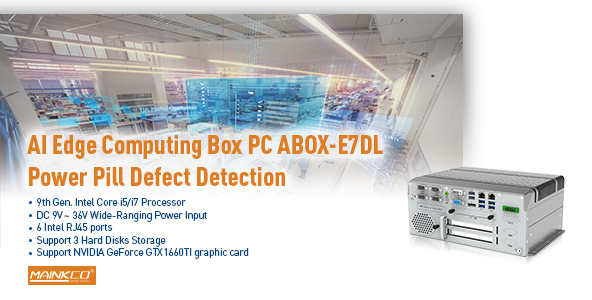

The platform layer mainly includes high-performance computing devices represented by GPU, a new-generation of computing technologies represented by edge computing and cloud computing, and high-performance storage platforms represented by cloud storage. The platform layer realizes the mining, analysis and prediction of manufacturing data through association analysis, deep learning, intelligent decision-making and knowledge reasoning, so as to provide a basis for the decision-making and regulation of intelligent manufacturing.

4)Application layer

The application layer is mainly responsible for the transformation and application of intelligent manufacturing technology under the background of 5G, including all kinds of typical products, production and industry solutions. Based on the advantages of 5G network of large-scale connection, large bandwidth, low latency, high reliability and so on, the research and development of a series of production and industrial applications, so as to meet the needs of digitalization and intelligence of enterprises. Application scenarios include: state monitoring, digital twin, virtual factory, human-computer interaction, human-computer collaboration, information tracking and traceability, etc. At the same time, with the further deepening of 5G technology, relying on data and user needs, the application layer can also provide users with accurate and personalized customized applications, so that the whole production is more compatible with the actual needs of users.

04

information safety

Information security is currently one of the major challenges facing various industries, including manufacturing. Emerging technologies, especially big data technology, have not only brought huge benefits to the manufacturing industry, but also made enterprises face huge information security risks. On one hand, because the industrial control system protocol is mostly in plain form, the industrial environment mostly adopts the general operating system and the update is not timely, the practitioners’ network security awareness is not high, coupled with the variety of sources of industrial data, with different formats and standards, so that there are many loopholes that can be exploited. On the other hand, in the industrial application environment, there are higher requirements for data security, and the occurrence of any information security incidents may threaten the enterprise information security, industrial production and operation safety and even national security. Therefore, good information security technology is an important basis and premise for the long-term safe and stable development of enterprises.

Information security is a comprehensive problem across multiple fields and disciplines, which needs to be studied in combination with laws and regulations, industry characteristics, industrial technology and other dimensions. At present, the commonly used information security technology system can be divided into three levels: information access security, information platform security and information application security. Among them, information access security provides security guarantee mechanism for industrial field data collection, transmission and conversion process; information platform security provides security guarantee basis for industrial data storage and computing; information application security provides strong security control for application access and data access.

1)Information access security

The security of information access must ensure the security of industrial edge equipment real-time data collection, remote state monitoring, system data extraction and other industrial data obtained from external systems, and anonymity, cleaning, conversion and transmission, so as to enter the complete data transmission chain of the industrial big data platform. The data collection side supports the registration and security authentication mechanism of the collection module to ensure the compliance of the data collection and application and the accuracy of the data collection; the edge calculation module supports the unified module management and signature verification mechanism to ensure the legality and reliability of the data pre-processing application; the data transmission channel supports channel encryption to ensure the confidentiality and integrity in the transmission process.

2)Information platform security

Information platform security is the security guarantee for the storage, access, computing and other functions of industrial data resources, including data storage security, computing security, platform management security and infrastructure security. Platform storage security supports data multiple backup setting and recovery mechanism, and adopts data access control mechanism to prevent over-access of data. Computing security supports computing initiator identity authentication and access control mechanism to ensure that only legal users or applications can initiate data processing requests. Platform management security includes security configuration of platform components, resource security scheduling, patch management, security audit, and etc., and strengthen data isolation and access mechanism for data “invisible”. The platform software and hardware infrastructure security includes basic network security and virtualization security, so as to ensure the safe operation of the entire data platform.